GUIDELINES FOR ODOR TREATMENT AT FOOD PROCESSING FACILITIES

A/ INTRODUCTION

Current status of the system needing treatment:

- The facility specializes in producing foods such as cakes, jams, candies, sausages, and other foods for the Tet holiday.

- The drainage system at the production facility is clogged, leading to slow drainage and an increasing occurrence of unpleasant odors. These odors originate from the facility's drains and extend to the common drainage system of the entire residential area, affecting the surrounding people.

- After a preliminary inspection, it was found that the facility's drains are clogged due to waste not being properly filtered before disposal, resulting in a thick layer of grease on the surface and a very foul smell.

Customer's requirements: Improve the system, unclog the drainage pipes, treat the unpleasant odors at the end of the pipeline, and minimize the impact on the surrounding people.

B/ Nature of the waste:

- During Tet, the demand for products increases significantly, requiring production facilities to double or triple their production capacity compared to normal demand. Increased production means an increase in the amount of waste generated.

- The production process involves various components such as starch, milk, sugar, and released fats, all contributing to unpleasant odors as the waste decomposes.

- If wastewater containing these components remains stagnant in the drains for too long, it will produce sour, fermented odors. The layer of grease, when cooled, will solidify into a mass, affecting the drainage process and generating foul smells.

C/ Treatment solutions:

- The drainage system at the production facility should be equipped with trash screens to filter out large waste particles, preventing clogging and ensuring that water does not stagnate.

- Regularly clear the drains, especially during holidays when production increases.

- Use bio-products to treat odors and regularly unclog the drains to reduce pollution, save time, and lower costs.

D/ Process of applying BIO-products for odor treatment:

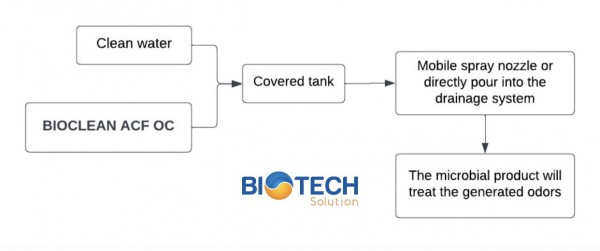

Procedure for spraying BIOCLEAN ACF OC bio-product for odor treatment.

Spray process diagram:

Usage norms for BIOCLEAN ACF OC:

- Mix BIOCLEAN ACF OC with clean, chlorine-free or Javel-free water at a ratio of 1:20 or 1:50 depending on the pollution level of the system.

- Stir well and cover tightly for 3-4 hours, then pour the diluted mixture into a spray bottle to treat odor-emitting areas, or pour directly into the drain to handle odors.

Notes:

- Stir well and cover tightly for 3-4 hours, then pour the diluted mixture into a spray bottle to treat odor-emitting areas, or pour directly into the drain to handle odors.

- The bioagent can help decompose 30-40% of organic matter.

- The treatment rate may vary depending on the actual waste odor, the degree of odor, and seasonal changes (rainy season, dry season, etc.).

- If odors persist at any location, spray the bioagent immediately at that location to eliminate the odor promptly.

Recommendations: Do not use this deodorizing product in conjunction with any chemicals that may affect the deodorizing process of BIOCLEAN ACF OC, as it will reduce its effectiveness.

Cautions:

- Staff at the waste site should wear gloves and masks when preparing the bioagent.

- Shake the product well before use.

- The diluted bioagent can be stored and used the next day.

- Add the required dilution water first and then add the deodorizing product.

- Avoid direct spraying of the deodorizing product on humans.

- Maintain the amount of bioagent to deodorize and limit insect development.

- Avoid excessive contact with skin, wash hands after use, may cause eye irritation, rinse with water, do not ingest.

- Store the product in a dry, cool place.

Technical support: Contact 0914.811.441 for detailed assistance

Home

Home